Fire bricks play a crucial role in structures that experience high temperatures, such as industrial furnaces, kilns, incinerators, and boiler fireboxes. They are made from heat-resistant clay that can withstand temperatures up to 2,800°F. The key property that determines a fire brick’s effectiveness is its brick melting point or the highest temperature at which it remains in a stable solid form.

A higher melting point of bricks means better heat resistance and durability under extreme heat. Here are details on the melting point and uses of various fire brick types:

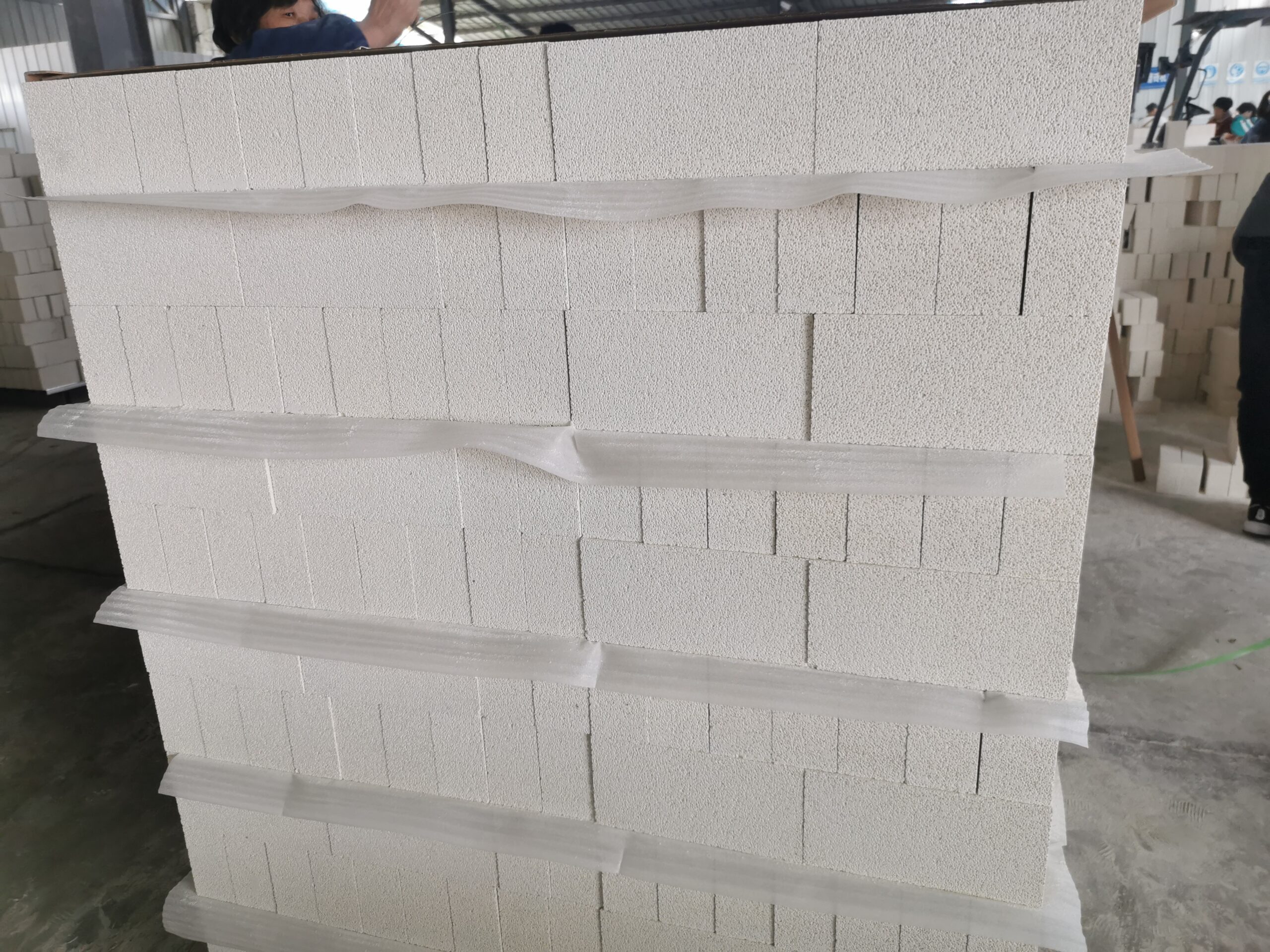

Bulk Fire Bricks

Bulk or common fire bricks are used as refractory linings in areas that experience medium to high heat. They provide thermal protection and insulation to metallic furnace structures. Most bulk fire brick is as made from fire clay and have a typical melting point ranging from 2,600°F to 2,900°F. Their low cost and good thermal resistance make them suitable for areas requiring medium refractory properties.

Side wall and back wall linings in furnaces and boilers are common applications of bulk fire bricks. They stabilize the heat within combustion chambers, reduce heat losses and extend the lifespan of metal components inside.

Refractory Bricks

Fire refractory bricks made from specialized materials like magnesite, chromite and zircon are used in applications with very high operating temperatures above 2200°F. They have higher content of alumina that increases their refractoriness and melting point in the range of 2,800°F to 3,300°F.

These high-quality fire bricks line critical furnace areas like the burner zone, roof and ducts that experience the maximum heat. They are suitable for glass furnaces, aluminum smelting furnaces and high temperature industrial kilns.

Quality Fire Brick Manufacturing By Manufacturer

Fire bricks are manufactured by mixing fire clay, fluxes and other additives in precise quantities. The raw materials undergo crushing, grinding and homogenization before being pressed and shaped into bricks. The green or unfired bricks are then dried and fired at temperatures up to 2,400°F in gas or oil fired tunnel kilns.

During firing, the major constituents in fire clay – silica, alumina and flux oxides – fuse together to form an impermeable ceramic with the desired strength, density and refractoriness. Proper firing also ensures that the fire bricks achieve their rated melting point.