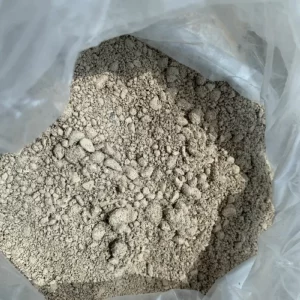

Plastic Castable

Showing the single result

Plastic castable is a powder material that is mixed with a liquid resin to produce a plastic compound that can be poured and molded into shapes. Some castables utilize a catalyst/inhibitor system to control working time and demold time.

Some Key Characteristics Of Plastic Castables Include

- Refractory plastic castable concrete set into rigid or semi-rigid plastic solids. The bound resin acts as a binder to hold the particles together.

- They can be poured into molds of various shapes and sizes. This allows them to be molded into complex geometries and parts.

- They require mixing with a resin or hardener to activate the curing process.

- Once mixed and poured, they cure through a chemical reaction between the resin and hardener.

Types Of Plastic Castable

- Firstly, made from epoxy resins and hardeners. They are durable, hard, and chemically resistant.

- Secondly, made from polyurethane resins and hardeners. They are flexible, lightweight, and impact resistant.

- Thirdly, made from acrylic resins and hardeners. They are clear, rigid, and transparent. Great for glazing, enclosures, and visual prototypes.

- Fourthly, good for prototype parts under high stress or temperature conditions. Polytek offers vinyl ester castables.

- Finally, made from thermoset polyurethane resins. Smooth-on offers these under their dragon skin line.