High alumina insulating brick is a type of heavy duty refractory made mostly of polycrystalline alumina. They contain around 55-85% alumina (Al2O3) and exhibit high heat resistance, strength, and durability at temperatures above 2,500°F. By combining heat protection, load support and energy efficiency in a single material, high alumina brick provides a comprehensive refractory solution for equipment operating under high heat industrial conditions.

Due to these properties, High Quality high alumina insulating brick represent an ideal insulation and structural liner material for equipment that operate at very high temperatures. Some key details about high alumina bricks include:

High Heat Bricks Resistance

The high alumina content in these refractory bricks confers them excellent heat resistance and load-bearing capacity at high operating temperatures. Their capability to withstand intermittent heatspikes up to 3000°F without degradation makes them ideal for applications like industrial furnaces,kilns, incinerators, and heat-treatment equipment.

The phase composition of high alumina bricks controls how well they perform at elevated temperatures. Various compositions are available to suit different duty cycles and operating temperatures ranging from intermittent 3000°F to continuous 2500°F.

Insulating Properties

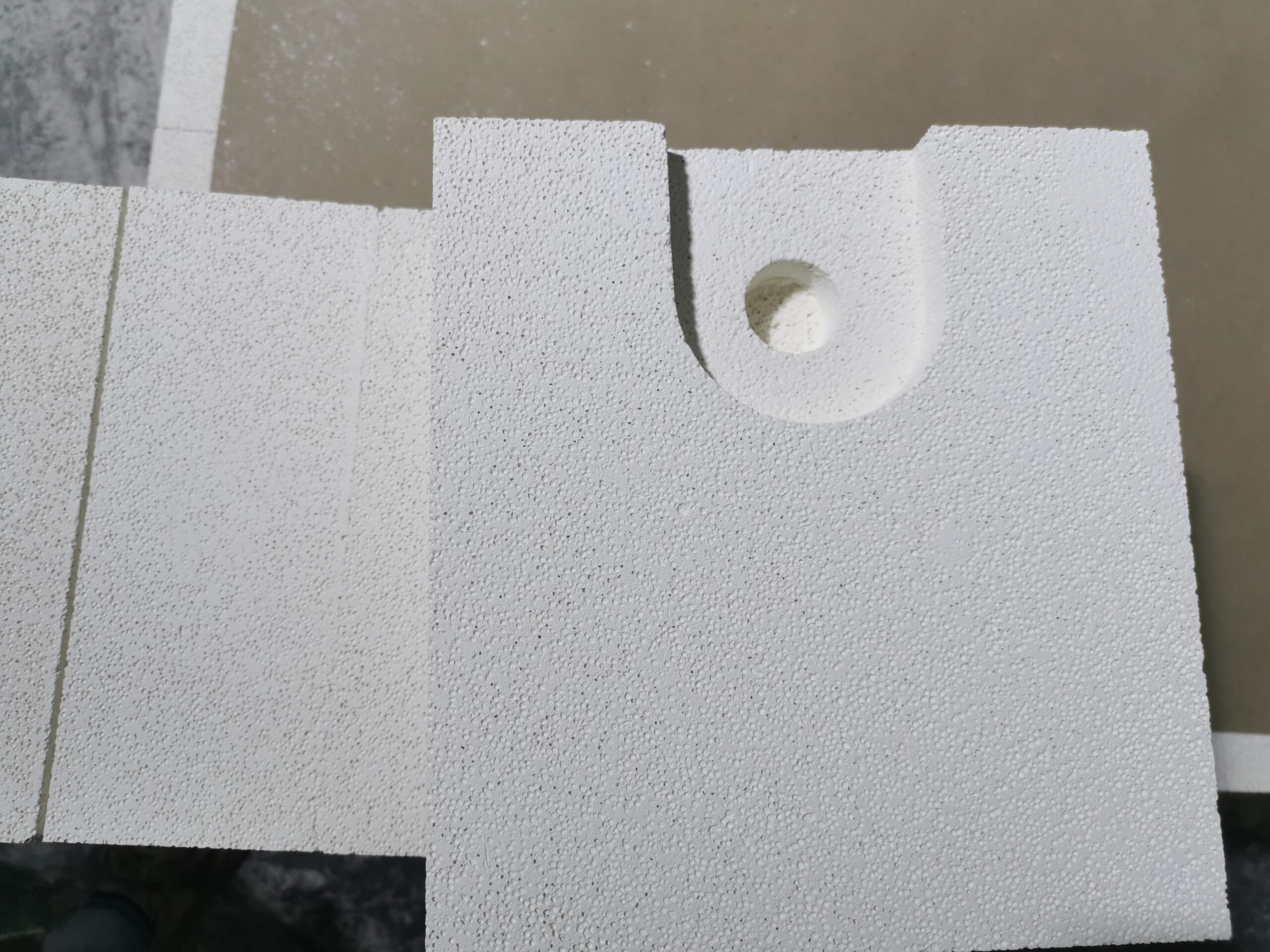

Besides heat resistance, high alumina bricks offer good insulating properties due to their porous structure and moderate thermal conductivity. They help maintain an even temperature distribution inside gas-fired and electric furnaces while reducing heat losses that impact efficiency.

The insulating performance of high alumina brick varies with its bulk density – lower density bricks have higher porosity and offer better insulation. Bulk densities range from 70 to 150 lbs/ft3 depending on the intended application and operating temperature.

High Strength & Durability

High alumina bricks by Fire Resistant High Alumina Brick Supplier, comprise mainly of alpha alumina gibbsite crystals formed during manufacturing under high temperatures. These crystals produce a strong interlocking microstructure that imparts high compressive strength to the refractory.

Since alumina is one of the most corrosion-resistant materials, high alumina bricks exhibit excellent resistance to slag, flue gases and other chemical corrosion at elevated temperatures. As a result, they provide durable thermal protection and structure support for long service life under extreme conditions.