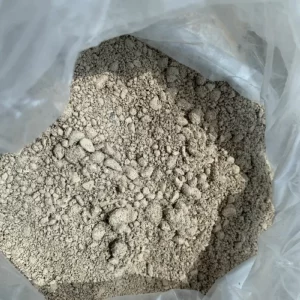

Unshaped Refractory Materials

Showing all 7 results

-

High Temperature Conventional Dense Castable Refractory Castable

-

High Temperature Refractory Castable Plastic Castable

-

Good Refractory Mortar Lining Mortar Firebrick Mortar

-

Refractory Castable Gunning Castable Ramming Gunning Mix Steel Mill

-

Good Performance Insulating Castable Insulation Castable

-

Low Cement Castable Refractory Castable

-

High Alumina Castable Refractory Castable

Categorization based on the process of production

There are many many classifications about unshaped refractory materials. Firstly, we will list the categorization according to its production process below:

- (i) dry press process,

- (ii) The process of fused casting,

- (iii) Process of molding by hand,

- (iv) A process for forming that includes normal, fired, or chemical bonding.

- (v) Unshaped refractories including monolithic, Plastic Castable, ramming masses, Gunning Castable, and castable, etc. and receive respective classifications.

Refractories Classified Based On Their Physical Form

Refractories are categorized based on their physical structure. The refractories can be shaped or unshaped. Refractory bricks are the common name for the shaped ones, while monolithic refractories describe the unshaped ones.

Refractories of fixed shapes are referred to as shaped refractories upon delivery to the user. Refractory bricks are commonly referred to as shaped refractories. Two types typically classify brick shapes.

- (i) Standard shapes

- (ii) Shapes that are unique or distinctive

What Are The Differences Between Shaped And Unshaped Refractories?

Refractories that are shaped are typically produced through machine pressing, resulting in an anticipated high level of property uniformity. Generally, special shapes are made by hand molding and are anticipated to display minor changes in characteristics.

Refractory that are unshaped lacks a specific shape and are formed only when they are applied. Monolithic refractories are better known for their jointless lining. Plastic refractories, ramming mixes, China Conventional Dense Castable, gunning mixes, fettling mixes, and Refractory mortars fall within specific categories.