PRODUCT

Product Description

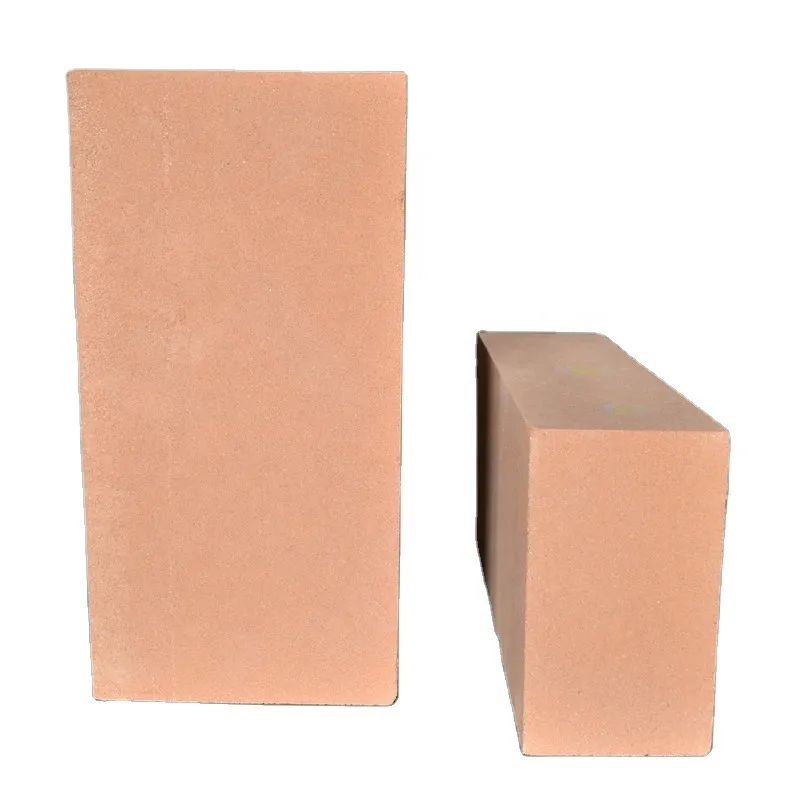

Light weight clay insulation brick is made of local top grade fireclay materials under the high temperature according to the lasted national standard, which possesses even bulk density, high strength, low thermal conductivity and low impurity.

Application

It is widely used as a primary hot face refractory lining or as back-up insulation behind other refractory in furnace(such as carbon furnace, cracking furnace, heating furnace for oil refining, roller kiln, tunnel kiln.), flues, refining vessels, heaters, regenerators and similar high temperature industrial equipment.

Parameter