ПРОДУКТ

Описание продукта

Gunning castable utilises specially selected raw materials including specific aggregate sizing, clays, cement and additives to ensure ease of placement by gunning methods. It can highly reduce installation time, cost and provide performance as good as refractory bricks and casting type castable. The gunning castable is a tendency in the future, it can highly save the construction time because you do not need to wait for the cooling of the operating area.

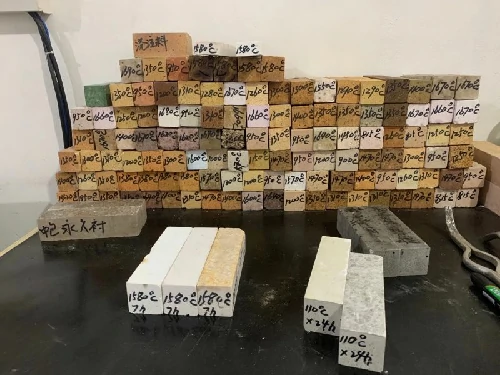

Параметр

Приложение:

Steel Industry,Energy Industry,Building Materials.It serves as a protective layer on the inner surface of blast furnace and hot blast furnace shells, as well as a working lining for blast furnace heads, coal gas outlet pipe, and dust collectors.

Картина